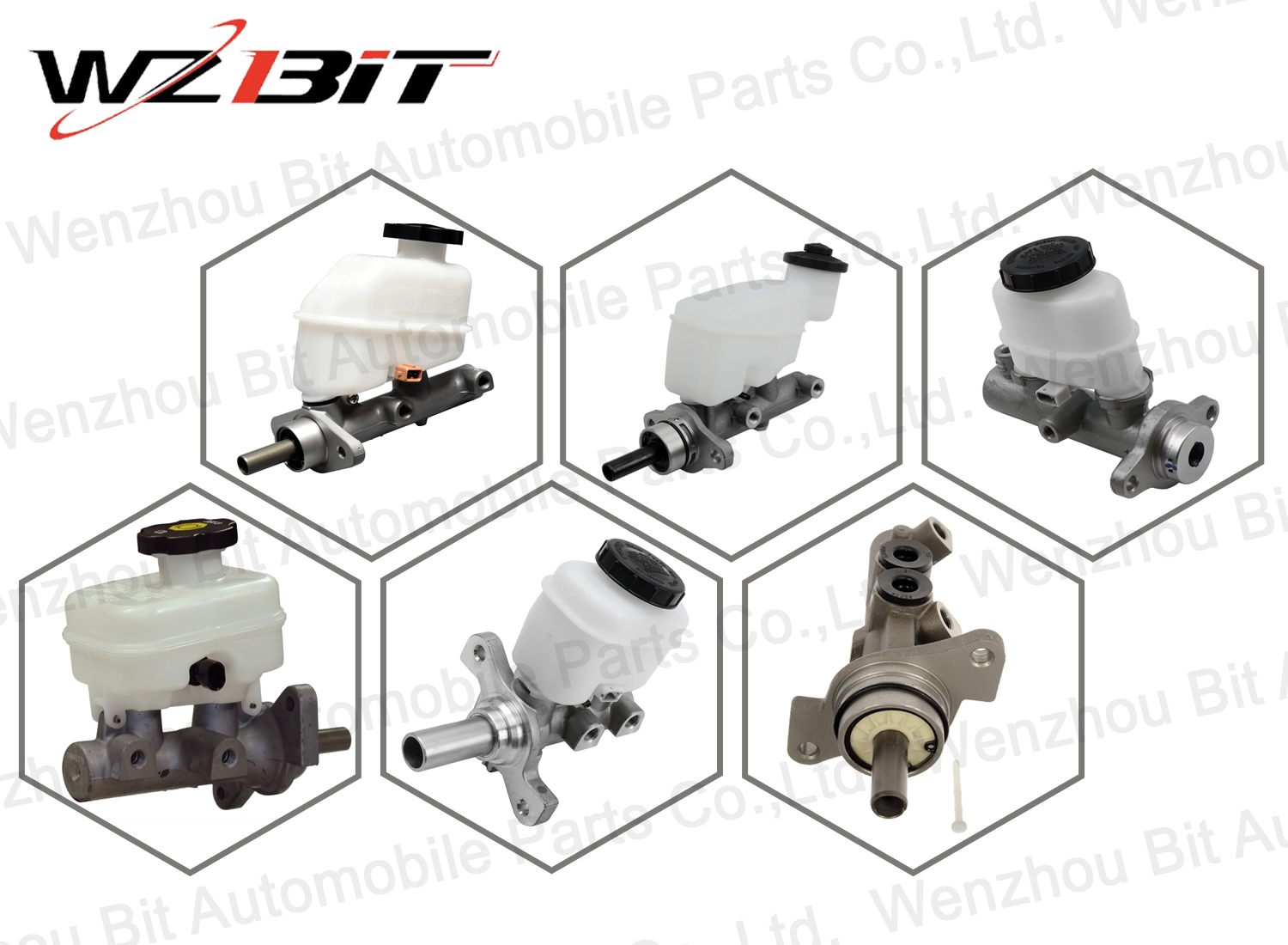

Brake Master Cylinder

The brake master cylinder is a crucial component in a vehicle's braking system. It serves as the heart of the hydraulic braking mechanism, converting the force applied by the driver's foot on the brake pedal into hydraulic pressure.

OE Nember

| 97FU2140BA |

| ZM97FU2140BA |

Compatible Applications

Car Fitment

Model

Year

Ford

Courier

1998-2005

2003-2007

FIESTA Saloon

2000-2013

Fiesta VI

2008-

Components and Functionality

1. Reservoir: - Function: Holds the brake fluid.

- Description: Typically made of plastic, this part is often mounted on top of the master cylinder. It ensures a constant supply of brake fluid to the system.

2. Piston Assembly:

- Function: Converts mechanical force into hydraulic pressure.

- Description: Consists of pistons and seals within a cylindrical housing. When the brake pedal is pressed, it pushes the piston(s) inside the master cylinder, creating hydraulic pressure in the brake lines.

3. Brake Lines:

- Function: Transmit hydraulic pressure to the brakes.

- Description: Metal or reinforced rubber tubes that carry the pressurized brake fluid from the master cylinder to the brake calipers or wheel cylinders.

4. Check Valve:

- Function: Maintains pressure within the system.

- Description: Prevents the brake fluid from flowing back into the master cylinder, ensuring that the hydraulic pressure remains stable.

Types of Brake Master Cylinders

1. Single-Circuit Master Cylinder:

- Usage: Older vehicles.

- Functionality: Controls the hydraulic pressure for the entire brake system through a single hydraulic circuit. Less common in modern vehicles due to safety concerns.

2. Dual-Circuit (Tandem) Master Cylinder:

- Usage: Modern vehicles.

- Functionality: Has two separate hydraulic circuits, enhancing safety by providing redundancy. If one circuit fails, the other can still function, allowing partial braking capability.

Operation

When the brake pedal is pressed:

1. The push rod connected to the brake pedal pushes the primary piston inside the master cylinder.

2. This movement pressurizes the brake fluid in the primary circuit.

3. If equipped, the secondary piston is also actuated, pressurizing the secondary circuit.

4. The pressurized brake fluid travels through the brake lines to the brake calipers or wheel cylinders.

5. The calipers or cylinders then press the brake pads or shoes against the rotors or drums, generating the friction needed to slow down or stop the vehicle.

When the brake pedal is released, the return springs in the master cylinder push the pistons back to their original positions, reducing the hydraulic pressure and allowing the brake pads or shoes to retract from the rotors or drums.

Maintenance and Issues

1. Brake Fluid Level:

- Regularly check and maintain the brake fluid level in the reservoir. Low fluid can indicate a leak or worn brake pads.

2. Brake Fluid Quality:

- Brake fluid should be periodically replaced as it can absorb moisture over time, reducing its effectiveness and potentially causing corrosion within the braking system.

3. Signs of a Faulty Master Cylinder:

- Spongy or sinking brake pedal.

- Brake fluid leaks.

- Reduced braking efficiency.

- Illuminated brake warning light.

Regular maintenance and prompt attention to any issues are vital for ensuring the safety and reliability of the vehicle's braking system.

Send your message to us: