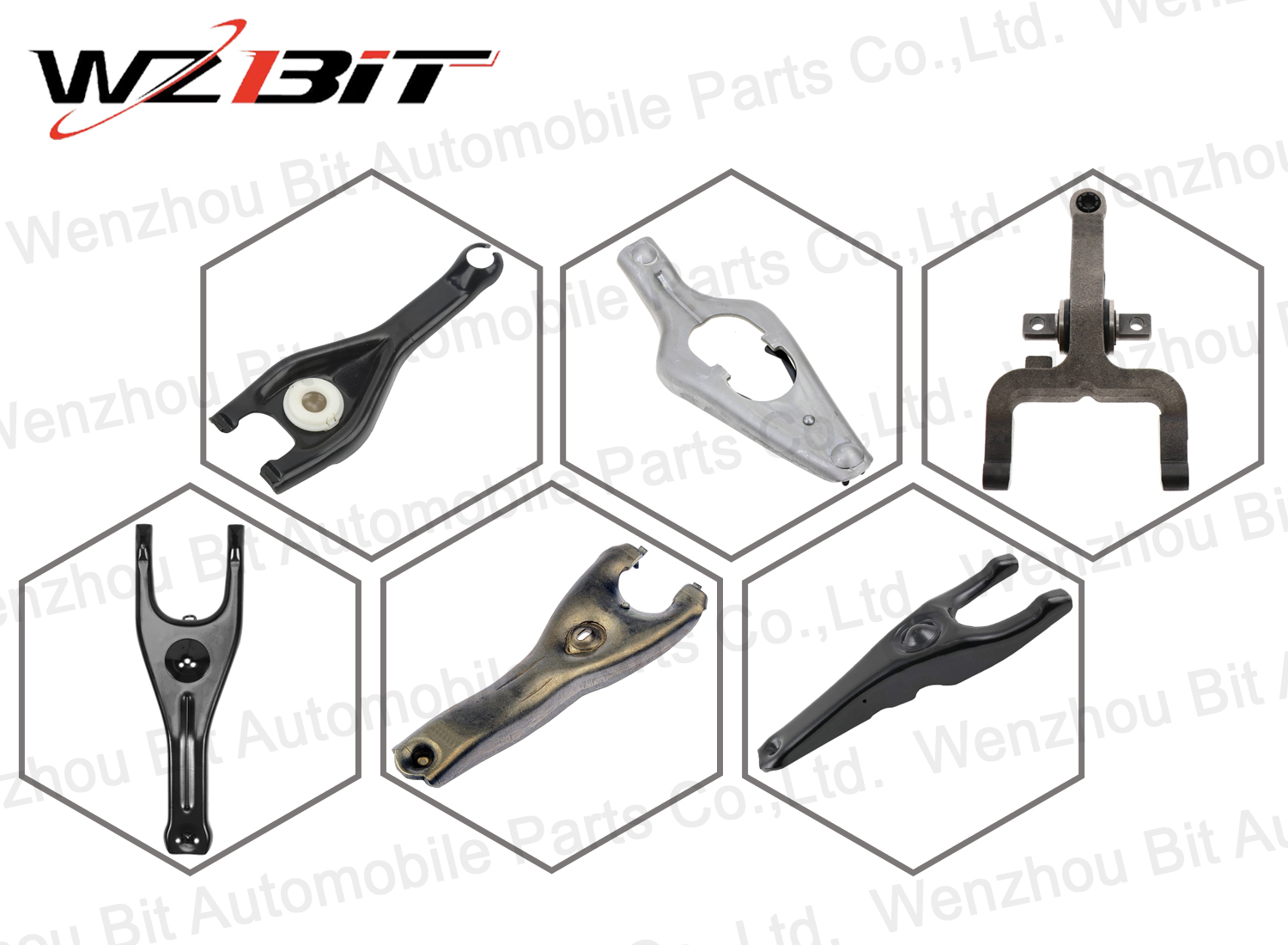

Release Fork, clutch

The clutch release fork, also known as the clutch fork, is an essential component in a manual transmission system. Its primary function is to engage and disengage the clutch by transferring the movement from the clutch slave cylinder or cable to the clutch release bearing.

OE Number

| 7700112818 | 7700875163 |

| 7700861585 | 7701478174 |

Compatible Applications

| DACIA Logan I Express (FS) (Year of Construction 03.2009 - ..., 75 - 87 PS, Petrol) |

| DACIA Logan I MCV (KS) (Year of Construction 02.2007 - ..., 75 - 105 PS, Petrol) |

| DACIA Logan I Saloon (LS) (Year of Construction 08.2004 - ..., 75 - 105 PS, Petrol, Petrol/Petroleum Gas (LPG)) |

| DACIA Sandero I (SD) (Year of Construction 06.2008 - ..., 72 - 87 PS, Petrol, Petrol/Petroleum Gas (LPG)) |

| RENAULT Clio I Hatchback (Year of Construction 01.1991 - 09.1998, 64 - 65 PS, Diesel) |

| RENAULT Clio II Hatchback (BB, CB) (Year of Construction 09.1998 - 08.2016, 58 - 179 PS, Diesel, Petrol, Petrol/Petroleum Gas (LPG)) |

| RENAULT Clio II Van (Year of Construction 09.1998 - ..., 64 - 80 PS, Diesel) |

| RENAULT Espace III (JE) (Year of Construction 11.1996 - 10.2002, 98 - 140 PS, Diesel, Petrol) |

| RENAULT Kangoo I (KC) (Year of Construction 08.1997 - ..., 54 - 95 PS, Diesel, Petrol) |

| RENAULT Kangoo I Express (FC) (Year of Construction 08.1997 - ..., 58 - 82 PS, Diesel, Petrol) |

| RENAULT Laguna I Estate (K56) (Year of Construction 09.1995 - 03.2001, 83 - 120 PS, Diesel, Petrol) |

| RENAULT Laguna I Hatchback (B56) (Year of Construction 11.1993 - 03.2001, 90 - 140 PS, Diesel, Petrol) |

| RENAULT Logan I Estate (KS) (Year of Construction 10.2007 - ..., 75 PS, Petrol) |

| RENAULT Logan I Saloon (Year of Construction 09.2004 - ..., 75 PS, Petrol) |

| RENAULT Megane I Classic (LA) (Year of Construction 09.1996 - 08.2003, 64 - 114 PS, Diesel, Petrol) |

| RENAULT Megane I Coach (DA) (Year of Construction 03.1996 - 08.2003, 90 - 147 PS, Diesel, Petrol) |

| RENAULT Megane I Hatchback (BA) (Year of Construction 01.1996 - 08.2003, 64 - 114 PS, Diesel, Petrol) |

| RENAULT Megane Scenic (JA) (Year of Construction 10.1996 - 10.1999, 64 - 114 PS, Diesel, Petrol) |

| RENAULT Sandero / Stepway I (BS_) (Year of Construction 02.2009 - ..., 87 PS, Petrol) |

| RENAULT Scénic I (JA0/1, FA0) (Year of Construction 09.1999 - 08.2003, 64 - 115 PS, Diesel, Petrol, Petrol/Petroleum Gas (LPG)) |

| RENAULT Symbol / Thalia I (LB) (Year of Construction 08.2000 - ..., 98 PS, Petrol) |

| RENAULT Twingo I Hatchback (Year of Construction 05.1996 - 06.2007, 54 - 60 PS, Petrol) |

Construction

A typical clutch release fork consists of:

- Fork Body: Usually made of steel or cast iron, with a forked design to straddle the clutch release bearing.

- Pivot Point: A central point where the fork pivots, allowing it to transmit linear motion into rotational motion.

- Push Rod Connection: The end of the fork connects to the push rod or the hydraulic slave cylinder.

- Bearing Contact Points: The ends of the fork contact the clutch release bearing, allowing for smooth engagement and disengagement.

Operation

1. Pedal Depression: When the driver presses the clutch pedal, the clutch master cylinder generates hydraulic pressure, which is transmitted to the slave cylinder or directly to the clutch release fork via a cable.

2. Fork Movement: The hydraulic pressure or cable movement pushes the clutch release fork, pivoting it around its central point.

3. Bearing Engagement: The pivoting action moves the clutch release bearing against the pressure plate, disengaging the clutch from the engine.

4. Pedal Release: When the clutch pedal is released, the hydraulic pressure is relieved or the cable retracts, and the clutch release fork returns to its original position, re-engaging the clutch.

Importance

- Smooth Clutch Operation: Ensures smooth and efficient engagement and disengagement of the clutch.

- Driver Control: Provides a mechanical link between the driver's input and the clutch mechanism, facilitating precise control.

- Durability: Designed to withstand the repeated stress of clutch operation, ensuring long-term reliability.

Maintenance

Regular maintenance and inspection of the clutch release fork are crucial for proper clutch operation:

- Wear Inspection: Check the fork for signs of wear or damage, especially at the pivot point and bearing contact areas.

- Lubrication: Ensure the pivot point and contact areas are properly lubricated to reduce friction and wear.

- Alignment: Verify that the fork is properly aligned and not bent or misaligned, which could affect clutch operation.

Replacement

If the clutch release fork shows signs of wear or damage, it should be replaced to maintain proper clutch function. Replacement typically involves:

1. Accessing the Fork: Remove the transmission to gain access to the clutch release fork inside the bell housing.

2. Removing the Fork: Disconnect the hydraulic slave cylinder or cable, and remove the fork from its pivot point.

3. Inspecting Components: Check the clutch release bearing and pivot point for wear and replace them if necessary.

4. Installing the New Fork: Install the new clutch release fork, ensuring it is properly aligned and secured at the pivot point.

5. Reconnecting Components: Reattach the hydraulic slave cylinder or cable and ensure proper adjustment.

6. Testing: Test the clutch operation to ensure smooth and consistent engagement and disengagement.

In Summary

The clutch release fork is a critical component that transmits the driver's input to the clutch release bearing, enabling smooth clutch operation. Regular inspection, maintenance, and timely replacement of the clutch release fork are essential for optimal vehicle performance and safety.

Send your message to us: